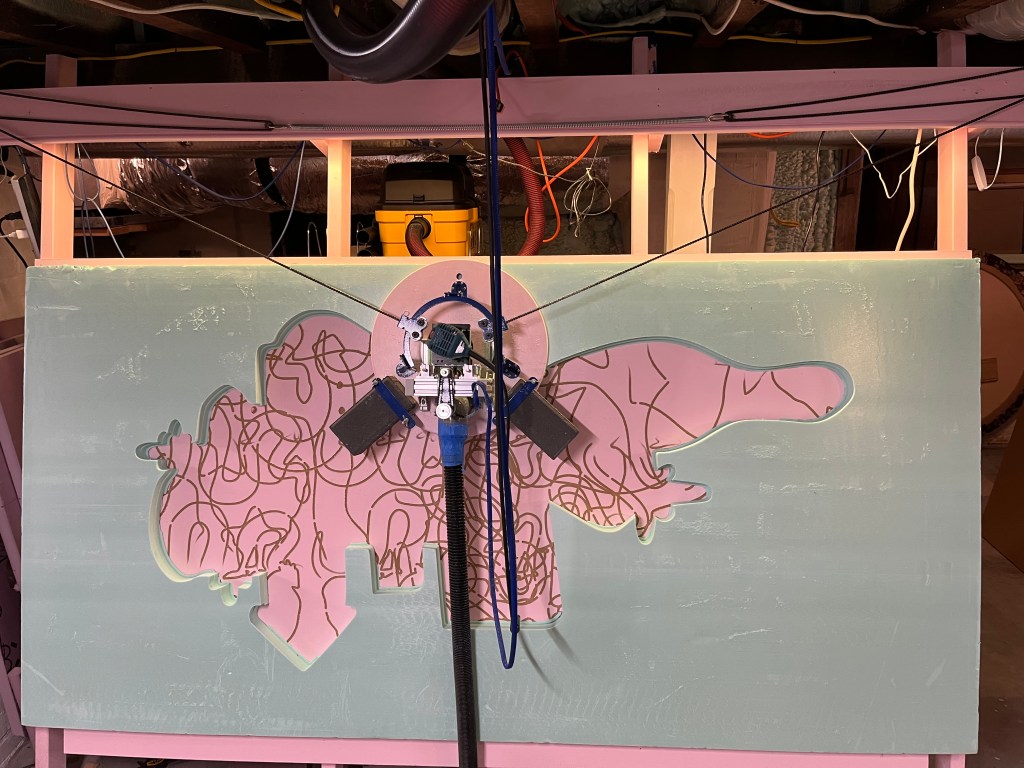

My sister is an artist. Her focus is mainly on oil painting and portraits, however she recently started using a hot knife to cut construction foam into different shapes to paint on. People seemed to really like her “shaped” artwork, however the process of manually cutting out the shapes each time is quite tedious work. This got me thinking if there were some easy way I could help her produce these shapes. I landed on the idea of some sort of CNC machine, but somehow much cheaper than most of the traditional types. I found a pretty novel design that the open source community had been iterating on, called the ‘Maslow’ CNC. It works by suspending the cutting part (in our case a Makita router) on two chains on an angled work surface, so the position of the cutter could be identified by chain length and work surface size, its actually a really elegant solution. I went ahead and ordered some parts, and built one in the basement of my parents’ house, which doubles as my sister’s art studio.

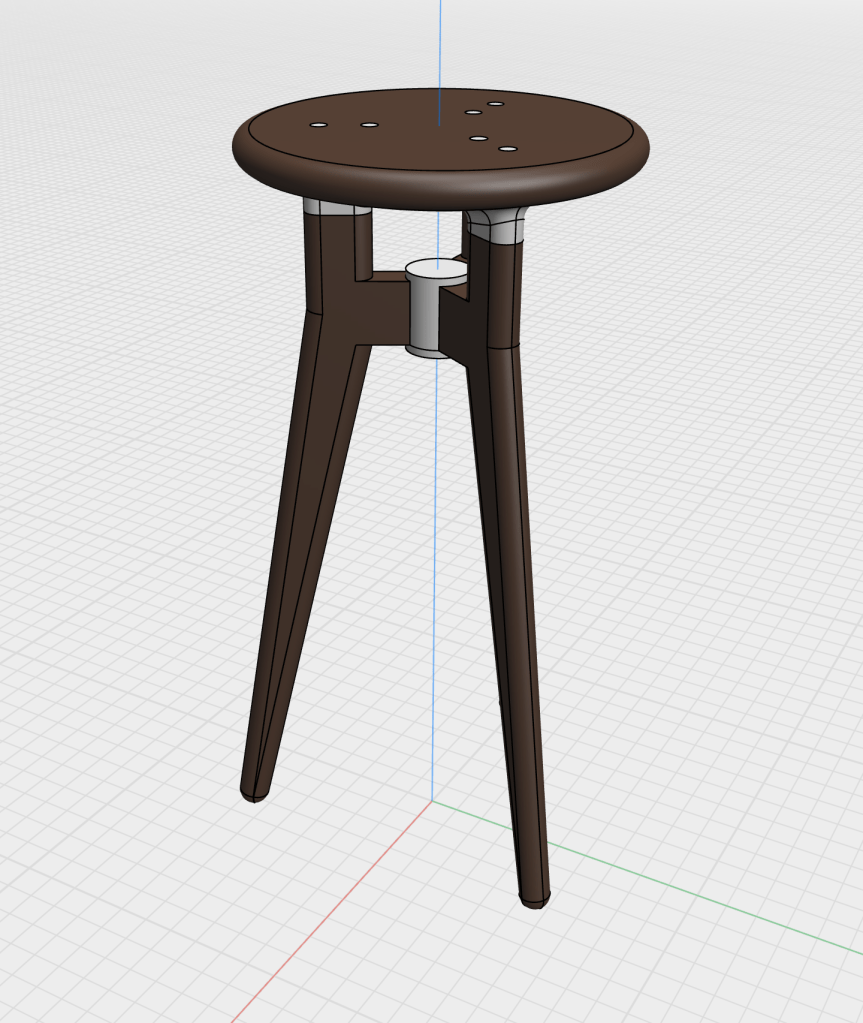

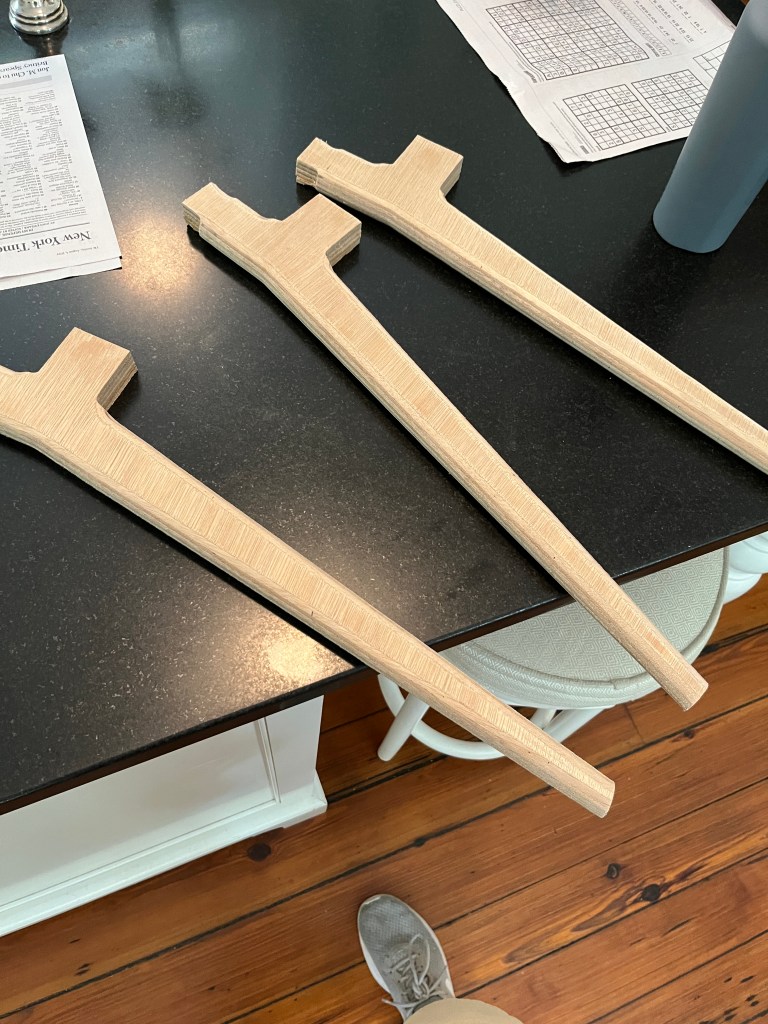

With the machine constructed and working great for cutting out foam, I had some growing ideas of what else the CNC could be used for. I got to work in Shapr3D designing a simple flat-pack stool that I could use to test tolerances and plywood cutting on the machine. After a few iterations, I now have side tables/stools for my living room, as well as for my sister’s art project.

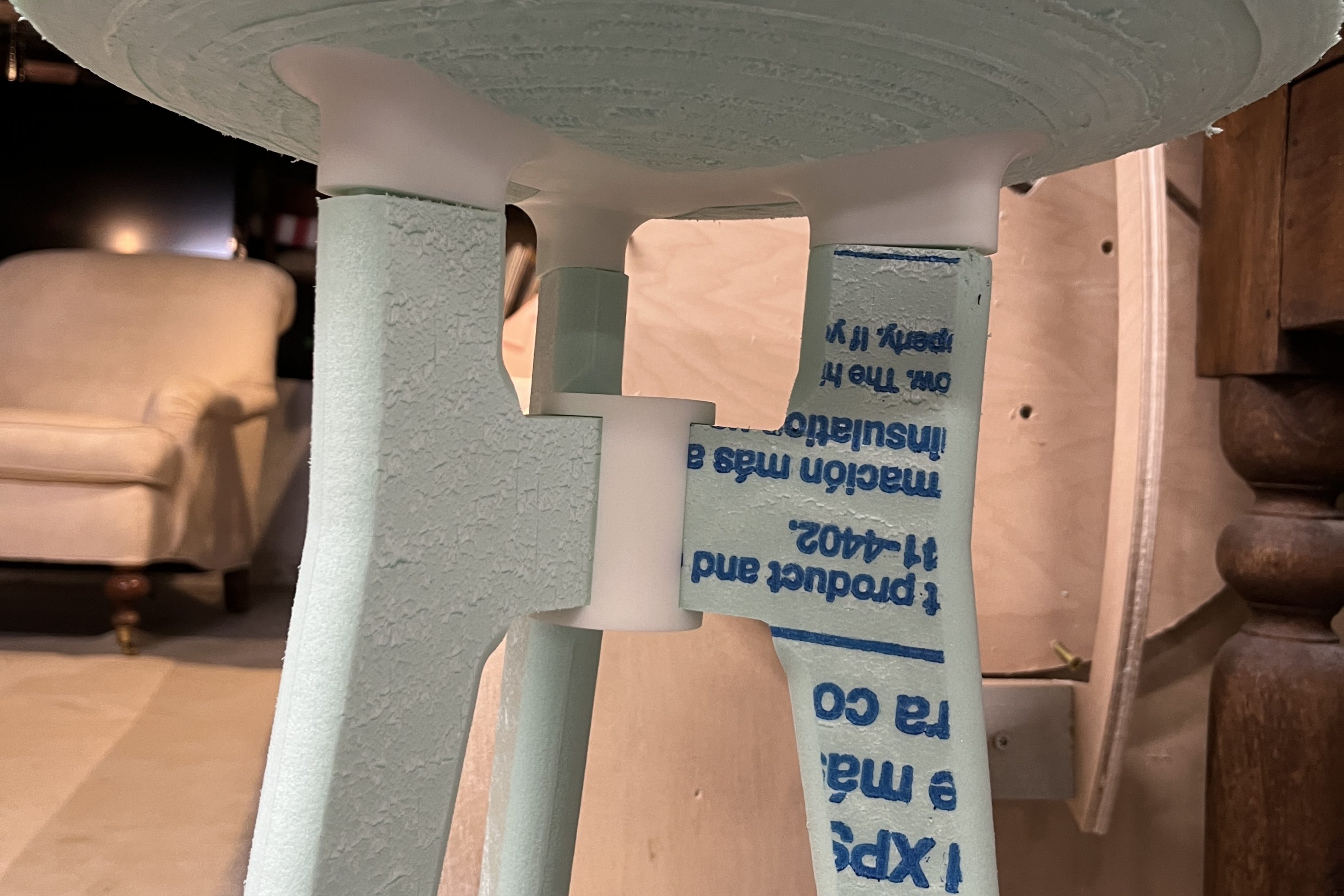

I had some friends come to stay with us for a week, and they loved the stool design, so I promised I would mail them one. After a few months, our friends got married and I still hadn’t sent them a stool. I was working on an updated stool design, to really push the limits of my woodworking ability, but to also test out PCBWay’s CNC aluminum feature. With one inch thich leg pieces, compound curve stool seat, and inlaid aluminum pieces, this was definitely a project that took me longer than expected. I started out building a rough prototype using construction foam and 3D printed pieces as stand-ins for the aluminum and wood.

After a few months though, and tracking down some nice marine-grade mahogany plywood, it was finally assembled and looking great. I built a custom cardboard box with custom foam cutouts to keep it stable in shipping.

The finishing touch were my friends’ initials on the middle piece of Aluminum. When my friends first got it, they had no idea I had made it until I showed them some work in progress pictures! They were pretty impressed, and their cat loves the custom box and foam.

Next up, an easier to build design, that might also include more inlaid aluminum…